Products by Manufacturer

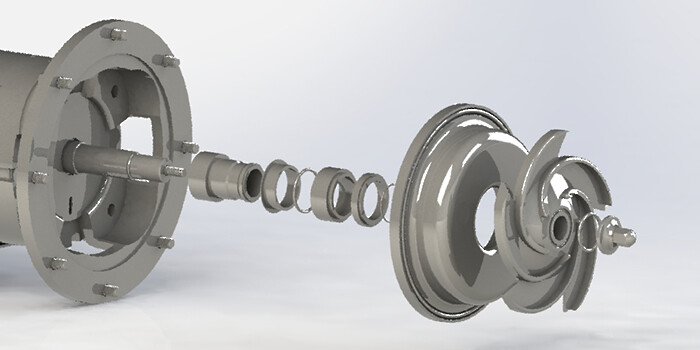

Ampco AC/AC+ Series Sanitary Centrifugal Pumps

The Ampco AC/AC+ Series of centrifugal pumps continue to lead the category in reliability and durability.

The AC/AC+ features a simplistic and sanitary design. Made from 316 stainless steel the AC/AC+ is corrosion resistant and is 3A Certified for sanitary use. In addition to performance and reliability, the AC/AC+ Series is designed to be completely interchangeable with other manufacturers’ pumps. Hydraulic characteristics and external dimensions are maintained for ease of replacement.

The AC+ takes the best of the AC Series pump and adds engineering innovation to the shaft design for better stability and increased performance. The simple yet ingenious design modifications of the threaded impeller nut and clamped stub shaft takes the traditional C Series and increases its reliability and clean-ability. The advanced shaft design of the AC+ reduces vibration, increases seal life and eliminates the less sanitary impeller pin design of the traditional C Series. While the pump enhancements mirror more expensive counterparts, Ampco remains committed to providing advancements at economical prices.

Max Discharge Pressure: 60 PSI / 4 BAR

Max Flow Rate: 920 GPM / 209 mᵌ/ hr

Max Viscosity: 1200 cP

Seal Specifications: 4 Seal Options

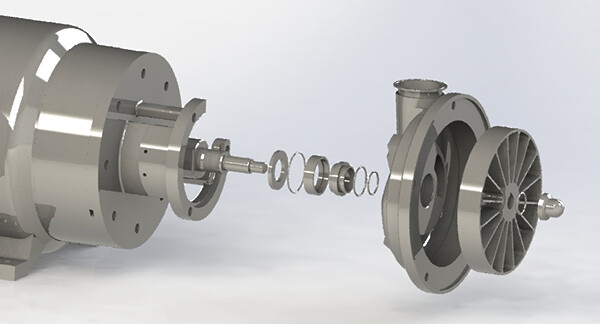

Ampco L Series Sanitary Centrifugal Pumps

The L Series centrifugal line-up is designed to offer gentle and efficient product handling capable of viscosities up to 1200 cP. All models are fully CIP-able (clean-in-place) and 3A certified.

Included in the L Series are models:

- LC featuring a single seal

- LD featuring double seal

- LF featuring front loading seal

- LME featuring front loading seal

- LH featuring high pressure handling

With their heavy wall cast and machined 316L stainless steel construction, 304 stainless steel adapters for corrosion resistance and a self-aligning shaft to extend seal life, the L Series pumps are built to last. Balanced impellers and tight manufacturing tolerances add to the efficiency of this durable line of pumps.

Max Inlet Pressure: 600 PSI / 41 BAR

Max Flow Rate: 1800 GPM / 409 mᵌ/hr

Max Viscosity: 1200 cP

Seal Specifications: 3 Seal Options

Ampco M Series Sanitary Centrifugal Pumps

The M Series high-efficiency, heavy-duty centrifugal pump is used for sanitary and non-sanitary applications worldwide. This pump is perfectly suited for CIP, water, juices, dairy and when modified – ideal for hot oil applications.

3A Certified for sanitary applications, the M Series provides several seal options and surface finishes for the utmost in application flexibility. Seal options include a standard Type 8B2 external seal, single or double internal seals, all offered in a variety of materials. The M Series comes close-coupled to NEMA Standard JM motors and requires minimal NPSH (Net Positive Suction Head).

Max Discharge Pressure: 175 PSI / 12 BAR

Max Flow Rate: 800 GPM / 181 Mᵌ/hr

Max Viscosity: 1200 cP

Seal Specifications: 3 Seal Options

Ampco SP Series Sanitary Centrifugal Pumps

The Ampco SP Series self-priming liquid ring pumps are ideally suited for products with entrained air and CIP return applications. Planned or unplanned, entrained gases are the cause of noise, vibration, seal failure, general performance reduction and eventual pump failure.

Designed to handle entrained gas conditions while maintaining specified performance and efficiency levels, Ampco SP Series pumps are built with extremely tight manufacturing tolerances.

A unique vane-shaped or wagon wheel style impeller design makes the SP capable of handling shear sensitive products efficiently while maintaining peak pump performance.

Max Discharge Pressure: 150 PSI / 10 BAR

Max Flow Rate: 275 GPM / 62 mᵌ/hr

Max Viscosity: 1,200 cP

Seal Specifications: 2 Seal Options

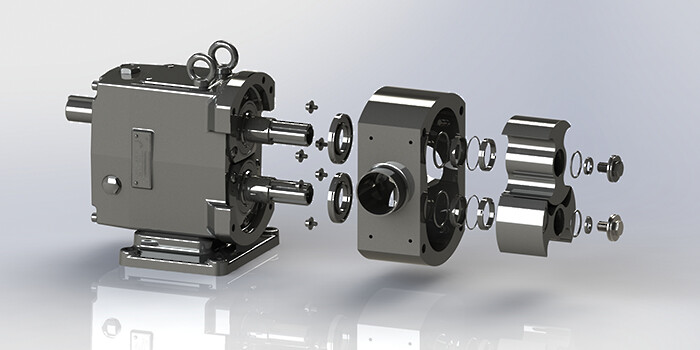

Ampco ZP Series Sanitary Lobe Pumps

The Ampco ZP Series pumps are leading the industry with their front-loading seals making them the most maintenance friendly designs in the sanitary market today. No longer do you need to remove piping for simple seal change and no more rust or paint chips on the processing room floor.

Well suited for high and low viscosity applications, Ampco’s ZP Series pumps are state-of-the-art 3A/ EHEDG Certified positive displacement pumps. The ZP Series circumferential piston pumps provide standard features and material upgrades that add to the durability of these workhorse pumps. A 304 stainless steel gearcase, stainless steel bearing retainers, stainless steel splash guards and one-piece 17-4 stainless steel shafts are STANDARD FEATURES on EVERY ZP SERIES PUMP.

Versatile enough to fit the most demanding sanitary or industrial application, Ampco Pumps offers more than 50 ZP models with over a dozen companion models featuring aseptic designs and rectangular flange configurations.

The full line of Ampco ZP positive displacement pumps has been developed to provide advanced features, material upgrades and tremendous maintenance advantages over competing pumps as their primary objective. Each model includes features that translate to value, efficiency, and longevity.

If one of our pump options does not fit your specific sanitary application, put our engineering team to work on tailoring a pump for your specific configuration.

Capacity Range: 0.1 to 310 gpm (0.02 to 70.4 m3/hr)

Pressure Range: Up to 500 psi/34 Bar

Temperature Range: -40⁰F to +300⁰F (-40⁰C to +150⁰C)

Hot clearances required for high temp operation

Viscosity Range: 1 to 1,000,000 CPS

Ampco AL Series Sanitary Lobe Pumps

The AL Series offers big value to the positive displacement pump market. This pump offers high level technology and performance at an economical price. Ampco’s AL Series pumps are well-suited for a variety of applications in the food, dairy, beverage and pharmaceutical industries with viscosity ranges from 1 to 1,000,000 cP and self-priming capabilities up to 12 feet.

There are several optional features in the AL Series line-up providing maximum flexibility for each application.

Seal choices include double mechanical, single seal with flush, double lip seal, triple lip seal, single O-ring seal and double O-ring seal. Heating and cooling jackets are also available for temperature sensitive processing applications.

Multiple rotor options are a tremendous advantage to the AL Series. Four rotor configurations are available; single wing, double wing, tri-lobe or multi-lobe allow users to customize the AL to their specific application requirements.

All AL pumps are 3A and EHEDG certified.

Max Discharge Pressure: 290 PSI /20 BAR

Max Flow Rate: 440 GPM / 100 m3/hr

Max Viscosity: 1,000,000 cP

Seal Specifications: 5 Seal Options

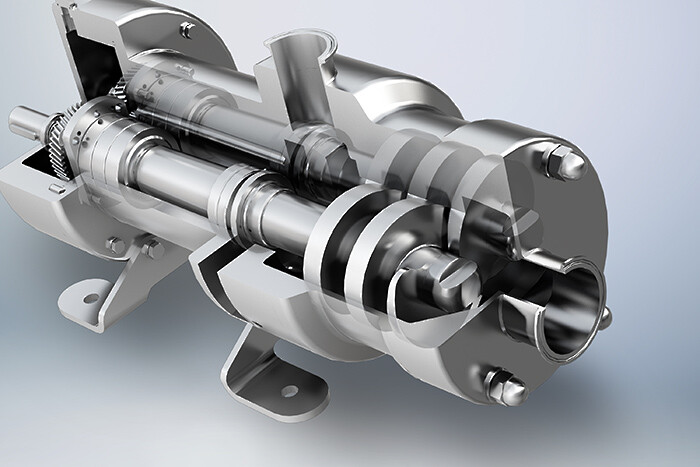

Ampco SLH Series Sanitary Twin Screw Pumps

Ampco Pumps is proud to introduce the Bornemann SLH Series of sanitary twin screw pumps. As the leader in twin screw pump technology, Bornemann designed the first model nearly 100 years ago. Ampco has now joined forces with Bornemann to offer this industry-leading hygienic twin screw technology to the U.S. market. The partnership brings a tremendous level of product inventory to North America and provides the support, service and delivery you have come to rely on from Ampco Pumps.

The SLH models are offered in two configurations: SLH-4U standard model and the SLH-4G premium design. Both models are 3A and EHEDG certified for sanitary standards and provide tremendous capabilities. Product handling features include a maximum viscosity of 1 million cP, pressure rated over 360PSI/25bar, flow rates over 1300 GPM/300m³/hr and particle sizes as large as 2.3”/58mm.

Designed for the gentle handling of soft solids and viscous products, the SLH is virtually pulsation-free. Being capable of processing and CIP (clean-in-place) without additional pump requirements makes the SLH a dual duty pump.

Max Discharge Pressure: 362 PSI/25 BAR

Max Flow Rate: 1321 GPM/300Mᵌ/ hr

Max Viscosity: 1,000,000 cP

Max speed: 3000 RPM

Max Port Size: 6”/152mm

Max Particle Size: 2.3”/58mm

Max Temp: 392°F/ 200°C

Ampco Z Series Centrifugal Pumps

The Z Series high efficiency centrifugal pumps shine in applications where corrosion resistance is of the utmost importance. Applications range from the shipping industry to desalinization and reverse osmosis systems.

Z Series pumps are offered in 3 standard alloys; duplex 2205, 316 stainless steel and nickel aluminum bronze for superior corrosion resistance. Other alloys are also available like Hastalloy C, Alloy 20 and 316L stainless steel.

All Z Series pumps have ABS (American Bureau of Shipping) type approval and are available for fast delivery.

Z Series pumps are close-coupled to NEMA or IEC motors.

Max Discharge Pressure: 175 PSI / 12 BAR

Max Flow Rate: 3450 GPM / 784 Mᵌ/hr

Max Viscosity: 1,200 cP

Seal Specifications: 6 Seal Options

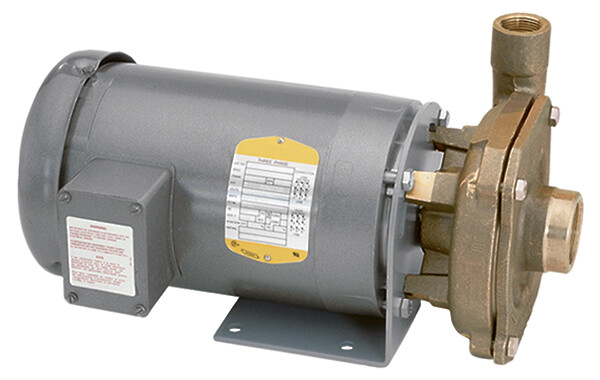

Ampco K Series Centrifugal Pumps

Ampco’s K Series line brings the same durability as the Z Series but in a smaller size. K Series high efficiency pumps have NPT threaded connections and are close-coupled to NEMA 56J frame motors. Available alloys include 316 stainless steel and nickel aluminum bronze. Duplex 2205 is also available.

All K Series pumps have ABS (American Bureau of Shipping) type approval and are available for fast delivery.

Features of the K Series include pressure capabilities as high as 150 PSI/ 10 BAR, temperature ratings as high as 225°F/ 105°C, multiple seal options and replaceable wear rings.

Max Discharge Pressure: 150 PSI / 10 BAR

Max Flow Rate: 230 GPM / 52 mᵌ/hr

Max Viscosity: 1,200 cP

Seal Specifications: 6 Seal Options

Ampco R Series Centrifugal Pumps

R Series self-priming pumps have been serving the shipping industry in fire and bilge pump applications for decades.

This versatile pump is capable of self-priming up to 25ft/7.6m. The R Series features include temperature ratings as high as 225°F/ 105°C, multiple seal configurations and compact close-coupled design.

All R Series pumps are close-coupled to NEMA or IEC motors. Available corrosion resistant alloys include 316 stainless steel and nickel aluminum bronze.

R Series pumps have ABS (American Bureau of Shipping) type approval and are available for fast delivery.

Max Discharge Pressure: 175 PSI / 12 BAR

Max Flow Rate: 475 GPM / 108 mᵌ/hr

Max Viscosity: 1,200 cP

Seal Specifications: 6 Seal Options

Ampco IC+ Series Centrifugal Pumps

The IC+ Series centrifugal pump is a cost effective solution for industrial applications where cast iron pumps are not recommended.

Constructed of 316L stainless steel, the IC+ offers a beaded finish fluid end with a 304 stainless steel adapter. The IC+ is built with a simple and common internal Type 21 single mechanical seal and the standard connection type is NPT or ANSI flanges.

The IC+ Series is an adaptation of the popular AC/AC+ Series sanitary pump and matches matching its hydraulic performance and external footprint.

Max Discharge Pressure: 60 PSI / 4 BAR

Max Flow Rate: 920 GPM / 209 mᵌ/hr

Max Viscosity: 1,200 cP

Seal Specifications: 1 Seal Option

Ampco D Series Centrifugal Pumps

Setting the standard for CIP supply for decades, the high efficiency D Series pump is a reliable and time tested CIP (Clean In Place) supply/return pump.

To aid in extended seal life, the D series is a closed impeller style pump. It runs quietly and efficiently.

The DV model offers a modified cover with a double volute design to reduce air binding, eliminating the need for an air relief valve.

D Series pumps are affordably priced and can handle temperatures as high as 400°F /204°C. Pumps come close-coupled to NEMA standard JM motors.

Max Discharge Pressure: 175 PSI / 12 BAR

Max Flow Rate: 630 GPM / 143 mᵌ/hr

Max Viscosity: 1,200 cP

Seal Specifications: 6 Seal Options