Products by Type

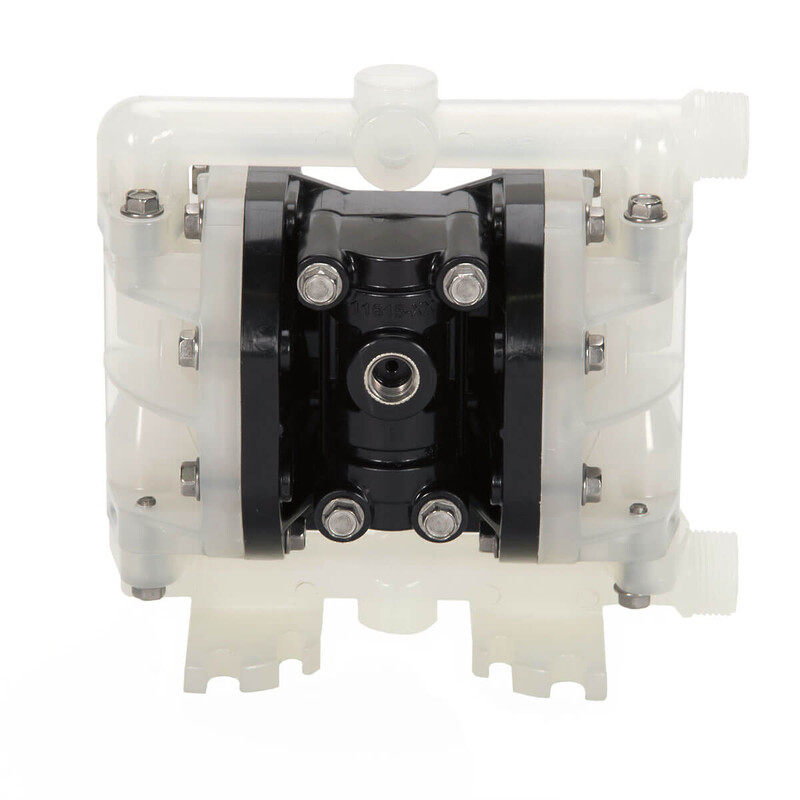

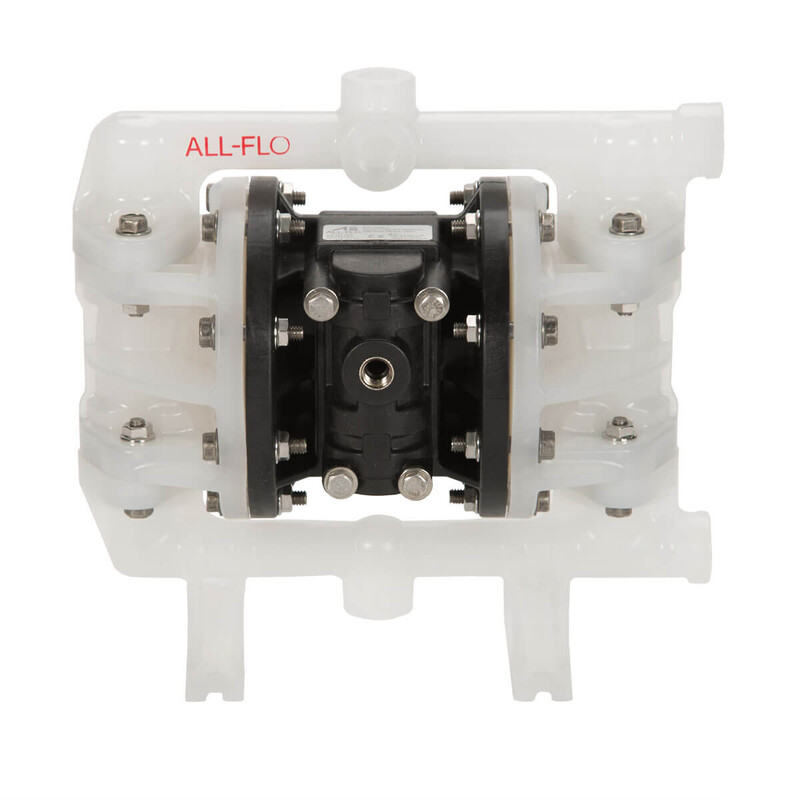

ALL-FLO 1/4'' Plastic Pumps

1/4" Plastic Pumps - Reliable polypropylene air section combined with a wide array of materials and elastomers ensure maximum chemical compatibility. Ideal for low volume clean fluids transfer applications.

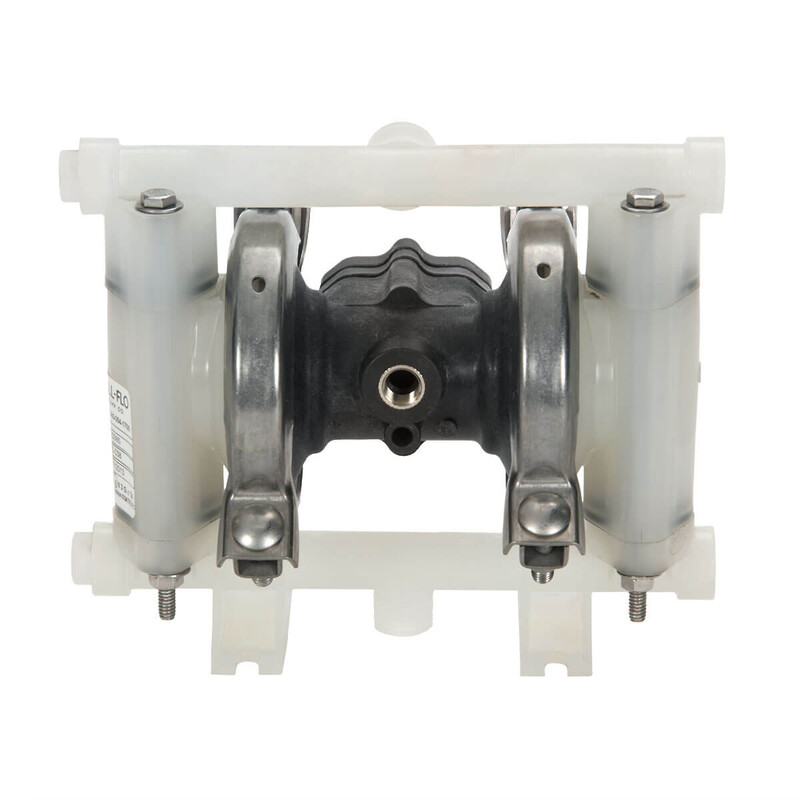

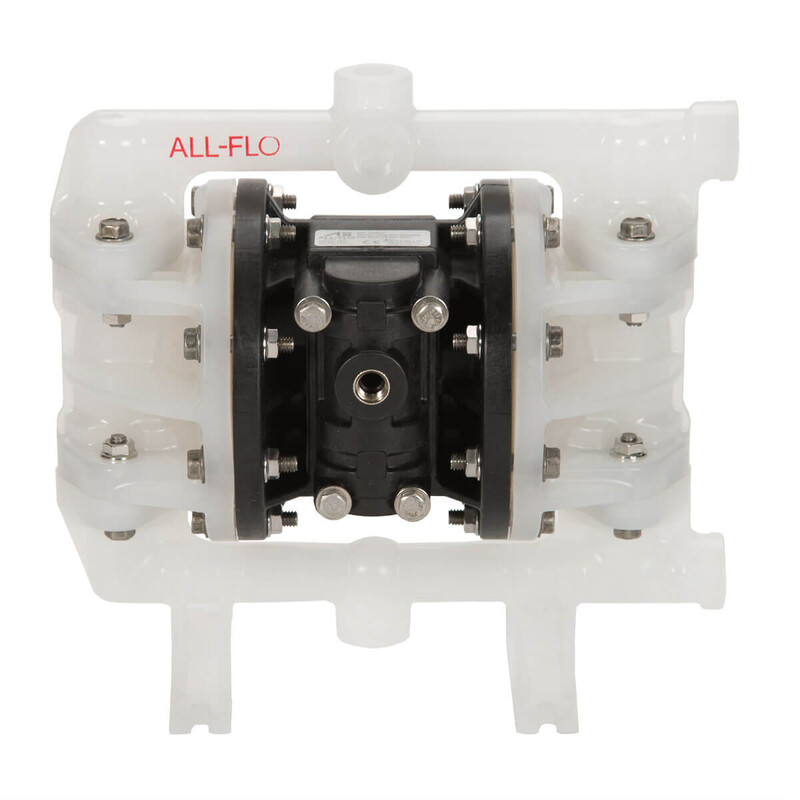

ALL-FLO 3/8'' Plastic Pumps

3/8" Plastic Pumps - Reliable polypropylene center section combined with non-metallic clamped casing and elastomer materials ensure maximum chemical compatibility. Ideal for low volume clean fluids transfer applications

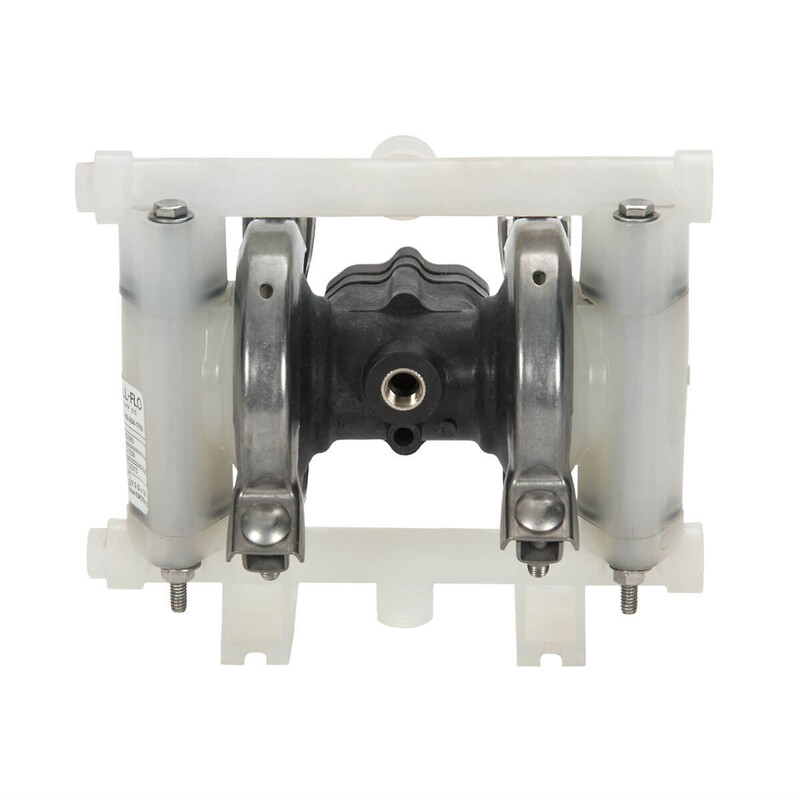

ALL-FLO 3/8" Plastic Pumps - Solids Handling Max-Pass

3/8" Plastic Pumps - Reliable polypropylene center section combined with non-metallic clamped casing and elastomer materials ensure maximum chemical compatibility. Ideal for low volume clean fluids transfer applications.

Our patented “Max-Pass” solids handling valve system allows operation under a variety of conditions, ranging from clean fluids to slurries to large solids as large as 1/4".

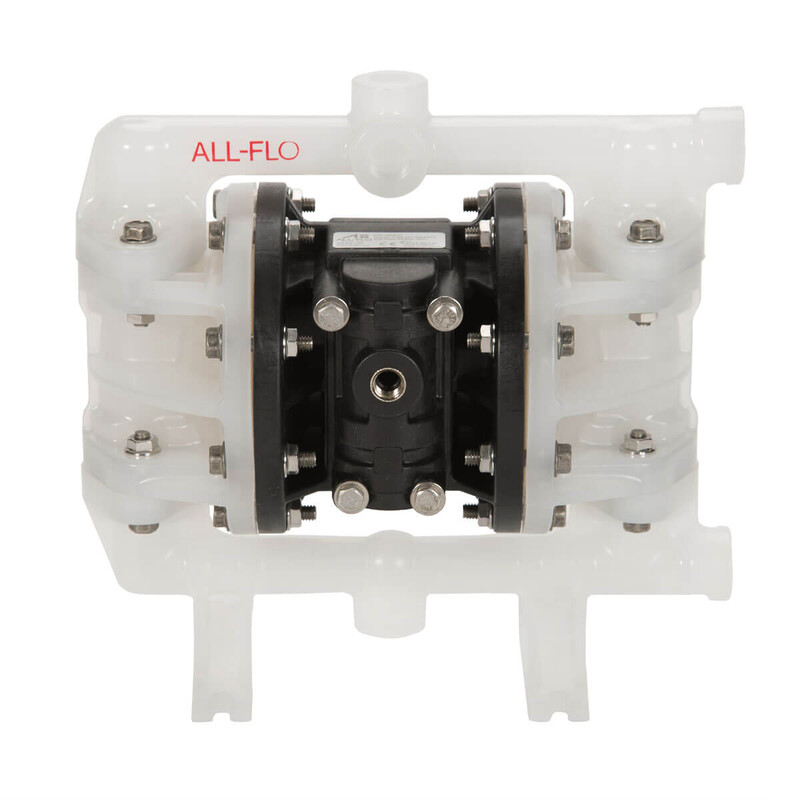

ALL-FLO 1/2'' Plastic Pumps

1/2" Plastic Pumps - Reliable polypropylene air center section combine with non-metallic casing materials ensure maximum chemical compatibility. Available in a variety of materials and options.

ALL-FLO 1/2" Plastic Pumps - Solids Handling Max-Pass

1/2" Plastic Pumps - Reliable polypropylene air center section combine with non-metallic casing materials ensure maximum chemical compatibility. Available in a variety of materials and options.

Our patented “Max-Pass” solids handling valve system allows operation under a variety of conditions, ranging from clean fluids to slurries to large solids as large as 3/8".

ALL-FLO 3/4" Plastic Pumps

3/4" Plastic Pumps - Engineered for maximum fluid and chemical compatibility. Heavy duty, stall free, non-metallic air section ensures stall free & freeze free operation. Bolted design provides ease of maintenance and leak free operation. Available in a variety of materials and options.

ALL-FLO 1" Plastic pumps

1" Plastic Pumps - Engineered for maximum fluid and chemical compatibility. Heavy duty, stall free, non-metallic air section ensures stall free & freeze free operation. Bolted design provides ease of maintenance and leak free operation. Available in a variety of materials and options.

ALL-FLO 1" Plastic Pumps - Solids Handling Max-Pass

1" Plastic Pumps - Reliable polypropylene air center section combine with non-metallic casing materials ensure maximum chemical compatibility. Available in a variety of materials and options.

Our patented “Max-Pass” solids handling valve system allows operation under a variety of conditions, ranging from clean fluids to slurries to solids as large as 1/2".

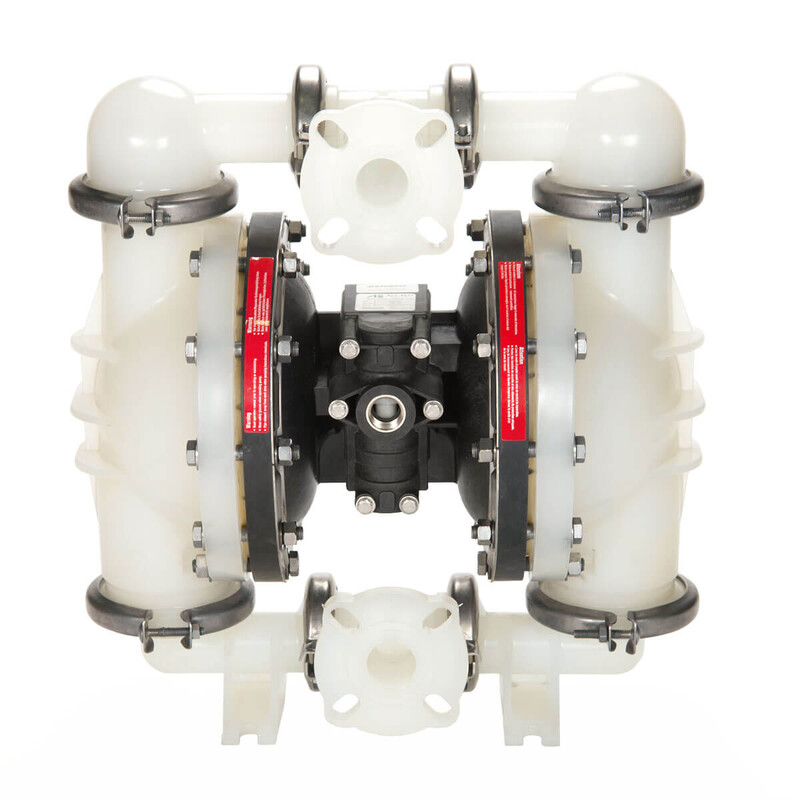

ALL-FLO 1-1/2'' Plastic Pumps

1-1/2" Plastic Pumps - Engineered for maximum fluid and chemical compatibility. Heavy duty, stall free, non-metallic air section ensures stall free & freeze free operation. Rugged valve system allows operation under a variety of conditions, ranging from clean fluids to slurries. Available in a variety of materials and options.

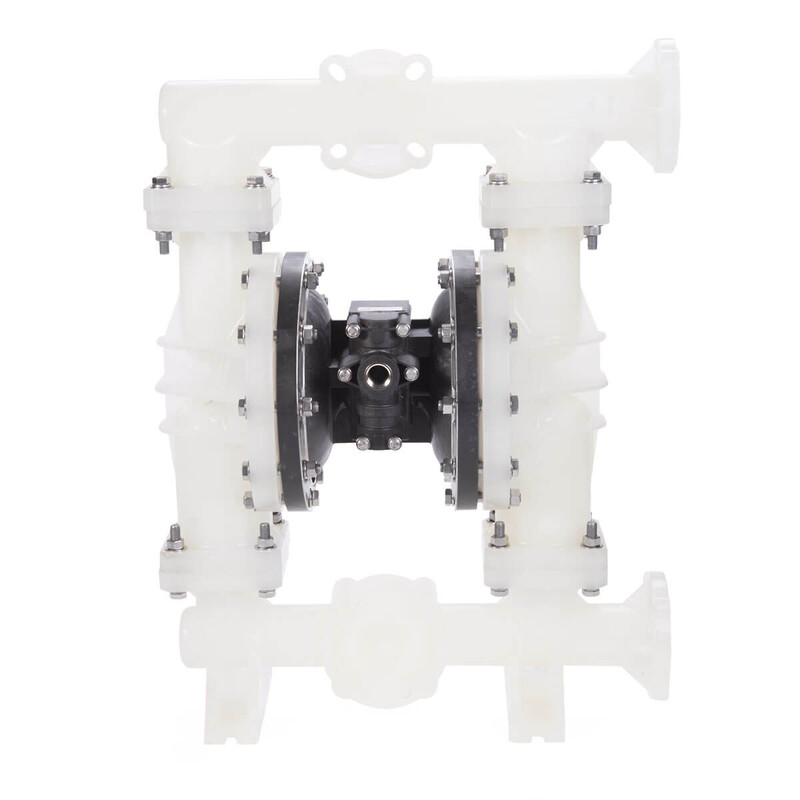

ALL-FLO 2'' Plastic pumps

2" Plastic Pumps - Engineered for maximum fluid and chemical compatibility. Heavy duty, stall free, non-metallic air section ensures stall free & freeze free operation. Rugged valve system allows operation under a variety of conditions, ranging from clean fluids to slurries. Bolted design provides ease of maintenance and leak free operation. Available in a variety of materials and options.

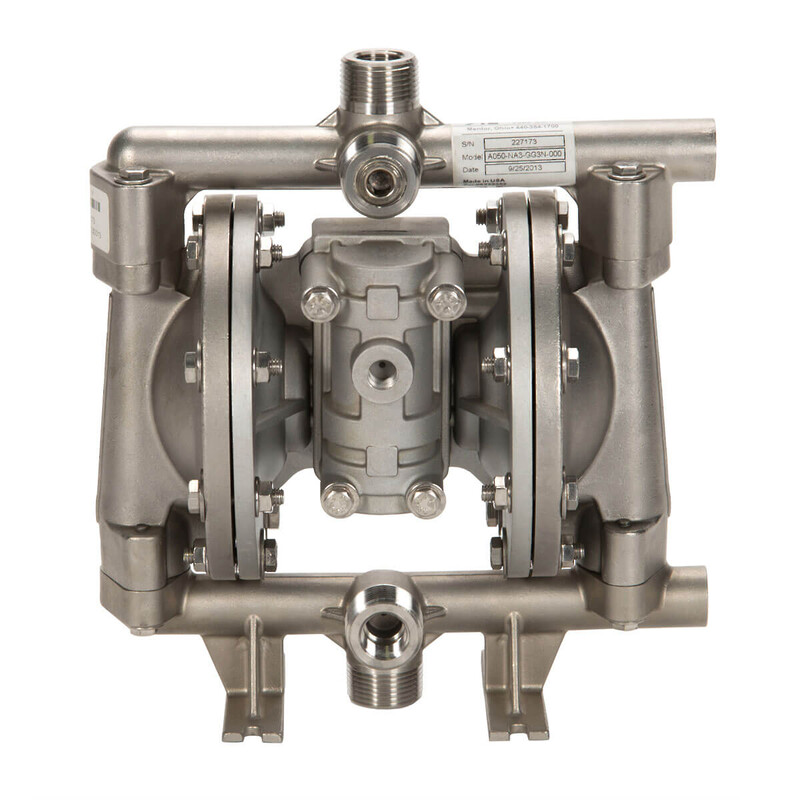

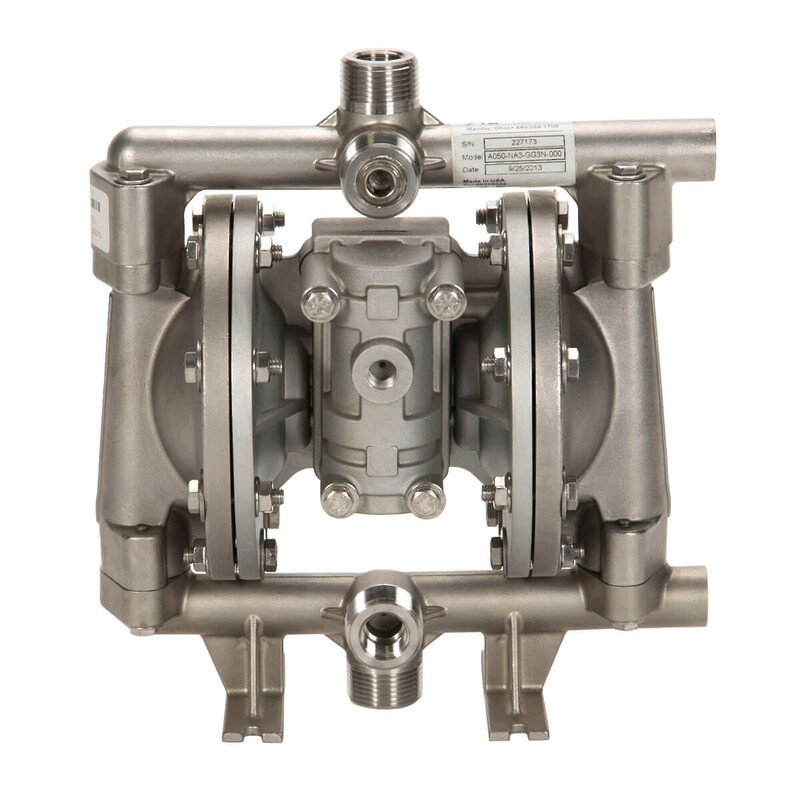

ALL-FLO 1/2'' Metal pumps

1/2" Metal Pumps - Flows up to 15 gpm (56.8 lpm) and maximum pressure to 120 psi (8.2 bar). Aluminum or 316 stainless steel wetted materials. Aluminum or polypropylene air sections with maximum suction lift of 15ft (4.5m) dry and 31ft (9.4m) wet. Air Inlet 1/4 inch FNPT with 1/2 inch FNPT (or BSP) liquid ports.

ALL-FLO 1/2" Metal Pumps - Solids Handling MAX-PASS

1/2" Metal Pumps - Flows up to 15 gpm (56.8 lpm) and maximum pressure to 120 psi (8.2 bar). Aluminum or 316 stainless steel wetted materials. Aluminum or polypropylene air sections with maximum suction lift of 15ft (4.5m) dry and 31ft (9.4m) wet. Air Inlet 1/4 inch FNPT with 1/2 inch FNPT (or BSP) liquid ports.

Our patented “Max-Pass” solids handling valve system allows operation under a variety of conditions, ranging from clean fluids to slurries to solids as large as 3/8".

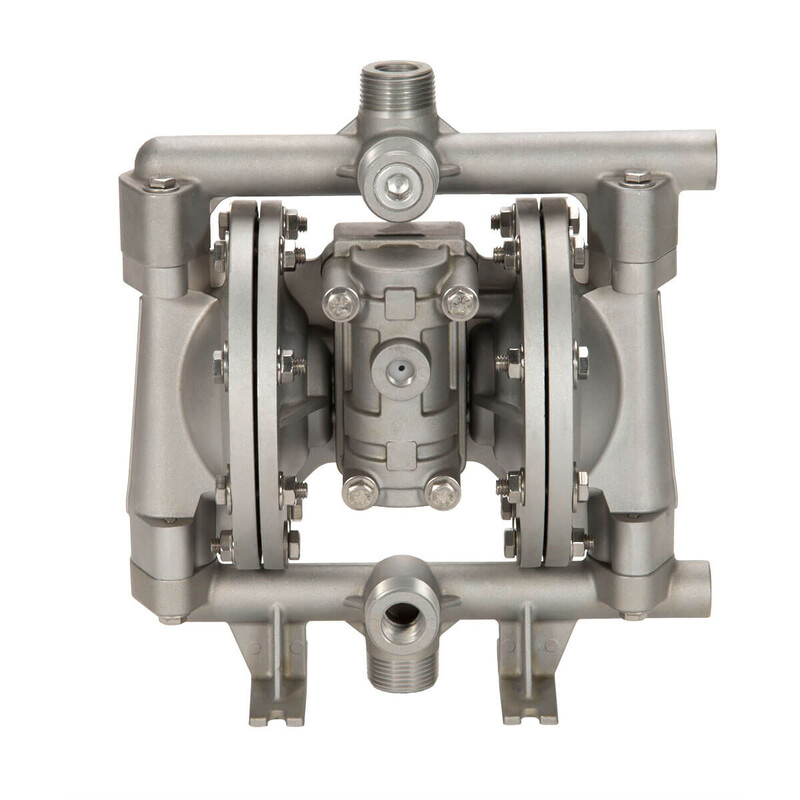

ALL-FLO 3/4" Metal Pumps

3/4" Metal Pumps - Flows up to 15 gpm (56.8 lpm) and maximum pressure to 120 psi (8.2 bar). Aluminum or 316 stainless steel wetted materials. Aluminum or polypropylene air valves with maximum suction lift of 15ft (4.5m) dry and 31ft (9.4m) wet. Air Inlet 1/4 inch FNPT with 3/4 inch FNPT (or BSP) liquid ports.

ALL-FLO 1" Metal pumps

1" Metal Pumps - Engineered for maximum fluid and chemical compatibility. Heavy duty, stall free, aluminum air section ensures stall free & freeze free operation. Bolted design provides ease of maintenance and leak free operation. Available in a variety of materials and options.

ALL-FLO 1" Metal Pumps - Solids Handling MAX-PASS

1" Metal Pumps - Engineered for maximum fluid and chemical compatibility. Heavy duty, stall free, non-metallic air section ensures stall free & freeze free operation. Bolted design provides ease of maintenance and leak free operation. Available in a variety of materials and options.

Our patented “Max-Pass” solids handling valve system allows operation under a variety of conditions, ranging from clean fluids to slurries to solids as large as 3/4".

ALL-FLO 1-1/2" Metal pumps

1-1/2" Metal Pumps - Engineered for maximum fluid and chemical compatibility. Heavy duty, stall free, aluminum or stainless steel air section ensures stall free & freeze free operation. Rugged valve system allows operation under a variety of conditions, ranging from clean fluids to slurries. Bolted design provides ease of maintenance and leak free operation. Aluminum units are available with either FNPT/BSP threaded ports or ANSI/DIN flanged ports and stainless units feature ANSI/DIN flanged ports.

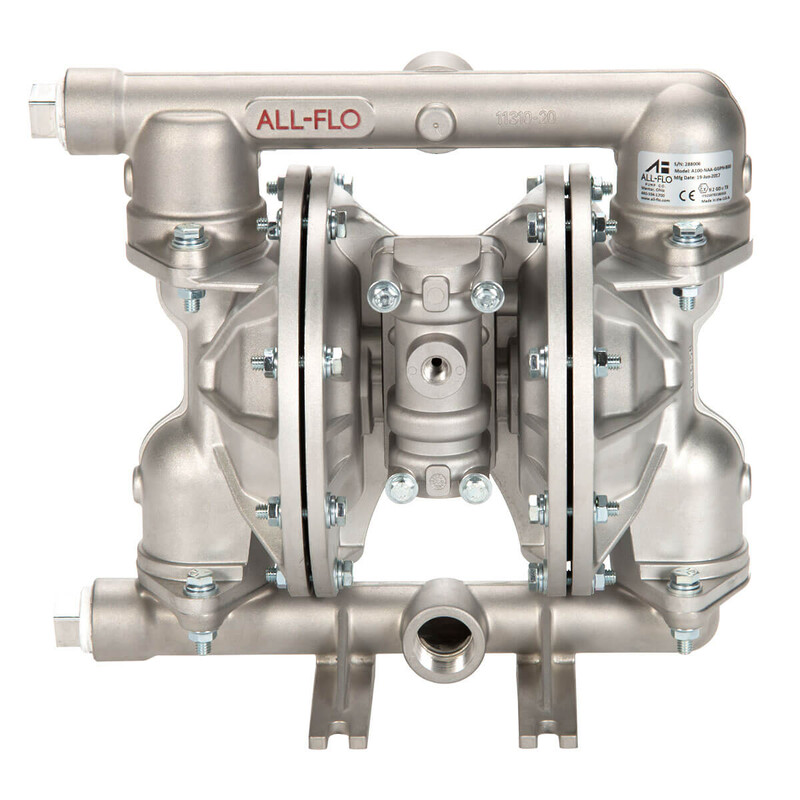

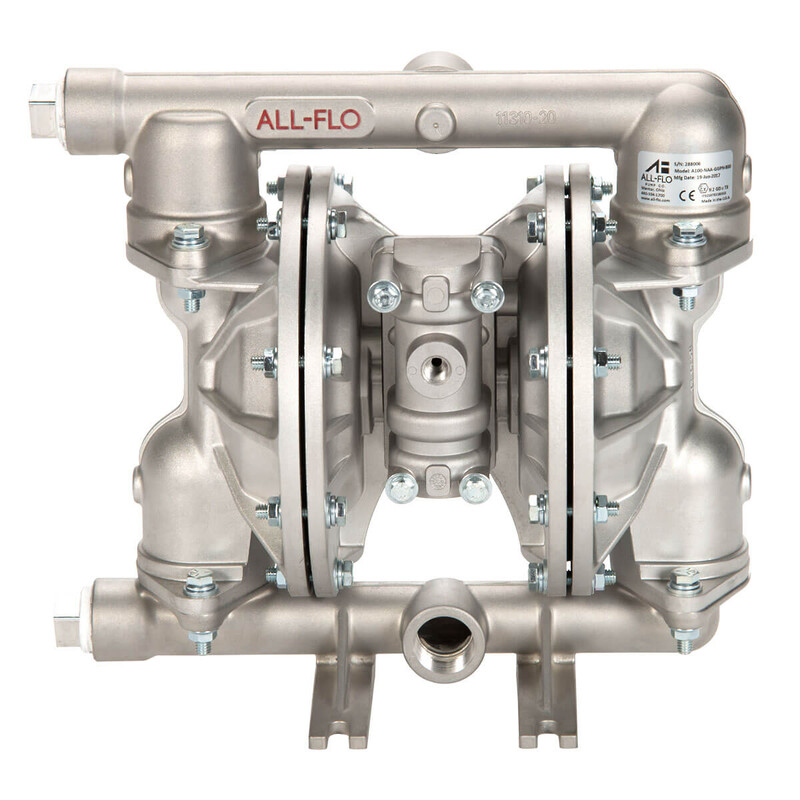

ALL-FLO 2'' Metal Pumps

2" Metal Pumps - Flow rates up to 190 gpm (719 lpm) and pressures up to 120 psi (8.3 bar). Maximum solids handled are 1/4" (6.4 mm) with a max suction lift of 24 ft (7.3 m) dry and 32 ft (9.8 m) wet. Air Inlet is 3/4" and standard porting is suction center and on end, discharge center and on end. Aluminum pumps feature FNPT/BSP threaded ports and stainless pumps feature ANSI/DIN flanged ports.

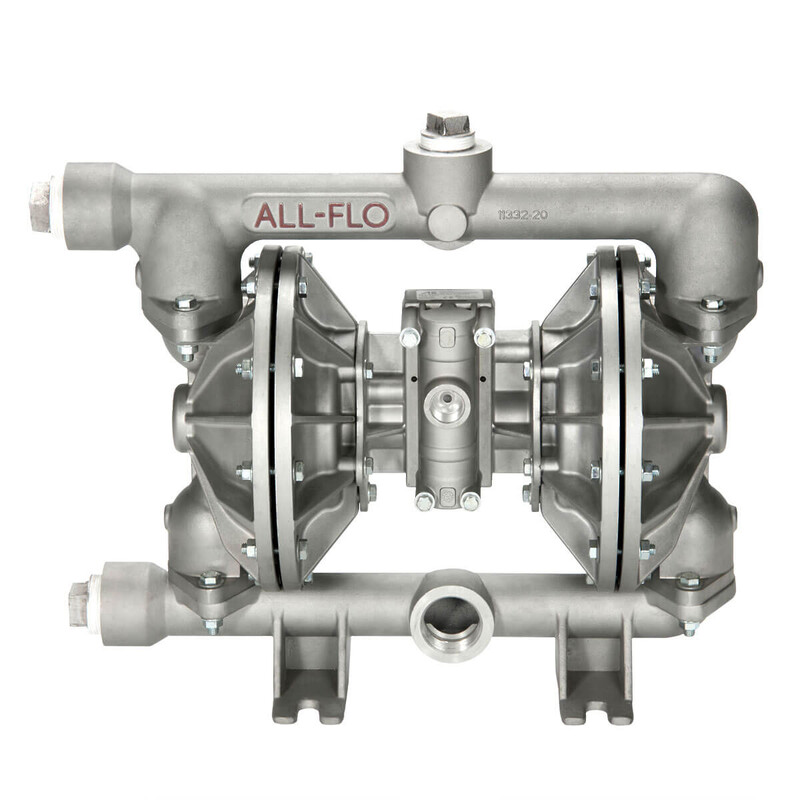

ALL-FLO 3" Metal pumps

3" Metal Pumps - Engineered for maximum fluid and chemical compatibility. Heavy duty, stall free aluminum air section ensures stall free & freeze free operation. Rugged valve system allows operation under a variety of conditions, ranging from clean fluids to slurries. Bolted design provides ease of maintenance and leak free operation. Aluminum pumps feature FNPT/BSP threaded ports and stainless steel pumps feature ANSI/DIN flanged ports.

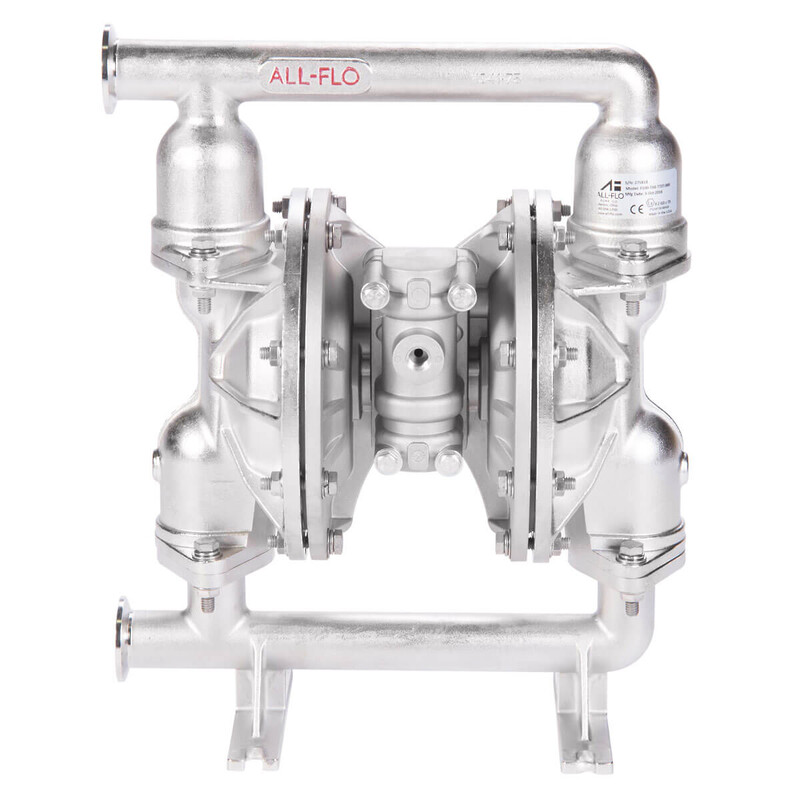

ALL-FLO All-Pur FDA F Series Pumps

All-Pur FDA F Series pumps offer a simple easy to maintain design with electro polished and passivated stainless steel wetted parts and aluminum or stainless steel air sections. F Series pumps are FDA, CE and ATEX compliant and are perfect for applications requiring a broad range of materials. Pump sizes are 1" (with 1-1/2" Tri-Clamp ports), 1-1/2" (with 2" Tri-Clamp ports) and 2" (with 2-1/2" Tri-Clamp ports).

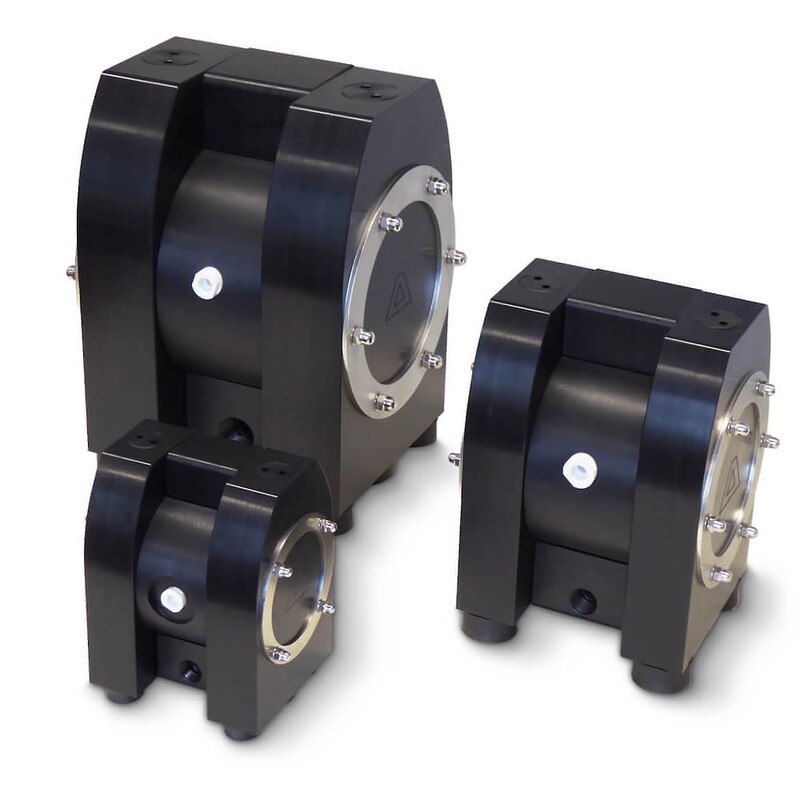

ALL-FLO All-Pur Food Grade G Series Pumps

All-Pur Food Grade G Series pumps offer a unique compact design with a conductive polyethylene air section and stainless steel wetted parts with one piece diaphragms and optional manual drain valves. G Series pumps are FDA, CE, ATEX and USP Class V1 compliant. Pump sizes are 3/4" (with 1" Tri-Clamp ports), 1-1/4" (with 1-1/2" Tri-Clamp ports) and 2" (with 2" Tri-Clamp ports).

ALL-FLO D Series Plastic Pumps

All-Flo D Series plastic pumps offer a reliable easy to service and compact design for use in high purity and chemical services. Pump sizes range from 3/8", 1/2", 1", 1-1/2" and 2" sizes with flows from 6 to 185 usgpm. Wetted parts are polyethylene, conductive polyethylene, PTFE, conductive PTFE and air sections are either polyethylene or conductive polyethylene.

ALL-FLO Drum Pump Kit

Drum pump kits allow for the convenient transfer of fluids from a 55 gallon drum. Each kit is made of compatible material and comes with a 40 inch tube (for maximum fluid transfer) and a bung adaptor (for connection to the drum). Drum Pump kits are available for all 1/4 inch, 3/8 inch, 1/2 inch and 1 inch pumps.

ALL-FLO Pulsation Dampeners

Pulsation dampeners are used to minimize potential pipe vibration and movement, reduce the forces exerted on the pump and to minimize or eliminate pulsation for spraying application or other downstream equipment. It works by means of an air cushion created by the pressure of the media pushing the diaphragm upward. This allows air to enter the chamber keeping the diaphragm center at midstroke. During operation, the diaphragm flexes thus absorbing and equalizing the pressure surge. Properly sized and installed, these dampeners provide a virtually surge-free discharge flow. Dampeners are available in connection sizes ranging from 3/8 inch to 2 inch and come in a range of materials and connections for compatibility with all of our pumps.

ALL-FLO Filter Regulators

All-Flo Filter Regulators both filter and regulate air supplies to control the air quality and cycle speed of an AODD pump. Available in sizes with air inlets of 1/4 inch, 1/2 inch and 3/4 inch for use with all sizes of All-Flo AODD pumps.

ALL-FLO Pump Grounding Lug Kits

All-Flo Grounding Lug kits are available for all sizes of All-Flo AODD pumps and should be used to comply with ATEX requirements where electrical grounding is required.

ALL-FLO Batch Controller

Batch controllers are available in two basic configurations. The Model B2 controller is engineered to provide control of the number of cycles produced by a solenoid-controlled AODD pump in batch applications. This handheld unit is locally controlled and programmed for individual batching and dispensing operations. The Model 420 controller is engineered to provide speed control of a solenoid-controlled pump that is linearly proportional to an external 4-20 ma signal. Both controllers should be used with our 12VDC solenoids. Solenoids are available in 12VDC, 24VDC, 120VAC or 220VAC and utilize a standard DIN 43650B or DIN 43640C connector, depending on the pump size. In addition to solenoid control, cycle counters are available on all pumps.

ALL-FLO Solenoid Control Accessories

In general solenoid control for All-Flo pumps are available in two types: on/off control and integrated pulse control for metering and dispensing applications. On/Off control are available with air ports in both 3/8 inch and 3/4 inch and thus can be used as an accessory on any available pump. Pulse control solenoids are factory installed in 1/4 inch, 3/8 inch, 1/2 inch and 1 inch pumps and can be used for dispensing applications with our B2 Batch Controller if integrated with a PLC. All solenoids are available in 12VDC, 24VDC, 120VAC or 220VAC and utilize a standard DIN 43650B or DIN 43640C connector, depending on the pump size. In addition to solenoid control, cycle counters are available on all pumps.

AMT 2" and 3" Diaphragm Pumps

The AMT line of Diaphragm pumps features a 2-stage, heavy duty forged gear driven transmission. Often referred to as Mud or Sludge Pumps, diaphragm pumps are designed to pump mud, slurry, sewage and thick liquids that have the ability to flow. AMT Diaphragm pumps are available with a choice of drivers to meet your application requirements: gasoline, diesel or single or three phase electric motor. Built-in check valve assures self-priming to 20 feet after initial prime. Heavy duty forged gear driven transmission is designed to operate pump at 40 strokes per minute for electric motor models and 60 strokes per minute for engine driven models. Each unit includes a 2” or 3” NPT steel suction strainer, two NPT nipples and a wheel kit for portability. Models 338E K6, 338G-K6, 337H-K6 and 337E-K6 are kits provided less motor or engine. Suction and discharge port sizes cannot be reduced.

• Sand Cast Aluminum Construction for Portability and Durability

• Thermoplastic Santoprene Diaphragm

• 2˝ or 3˝ NPT Suction and Discharge Ports

• Self-Priming to 25 Ft. Lift

• Maximum Solids Handling up to 1-5/8˝

• Modular Component Design Permits Easy Maintenance and Cleanout

• Driver Options: Gasoline, Diesel or Electric Single & Three Phase Motors

• Delivers up to 90 GPM

• 90° Rotatable Base on All Models